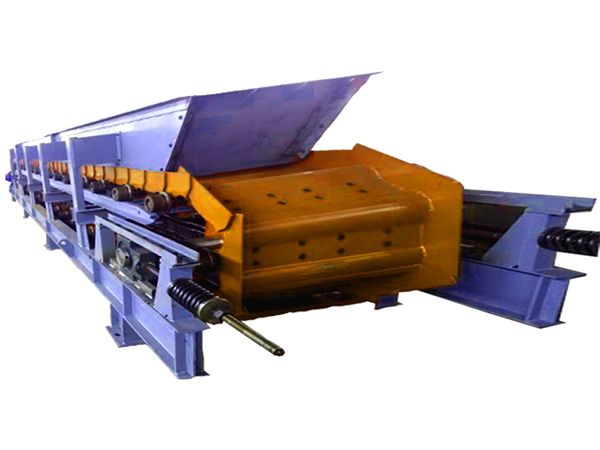

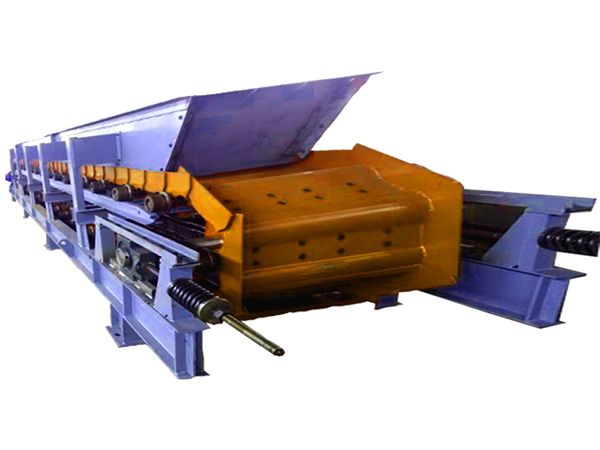

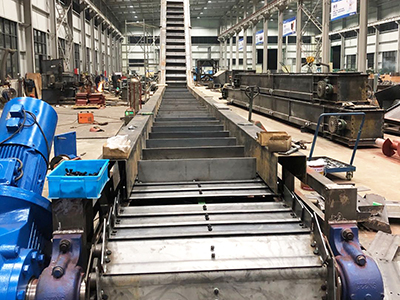

Plate chain trough conveyor

Plate chain trough plate conveyor is a kind of continuous material conveying machinery, which is used to continuously evenly distribute transfer materials to crusher, conveyor other working machinery along the horizontal inclined direction. It is suitable for loose, massive large feeding process in large medium-sized cement plant production line, can transport large blocks. It can work reliably in high temperature humidity harsh environment, especially for transporting large blocks large amount of materials It is suitable for mild sharp materials, can work reliably in open air humid harsh environment.

Plate chain trough plate conveyor (plate feeder) can be divided into: light plate feeder, medium plate feeder, heavy plate feeder. It is suitable for the continuous uniform distribution transportation the storage bin to the crusher conveyor other working machinery containers along the horizontal inclined line. The bulk density of the light machine is no more than 1200kg / m3, the block weight is no more than 140kg, the temperature is no more than 350 ℃. Medium sized machine is more than 2400 kg / m3, block weight is more than 500 kg, temperature is higher than 400 ℃ of various loose materials. The specifications of heavy plate feeder are 1000, 1250, 1500, 2000, 2500, 3150 mm in width, 420 m in length 60-200 m3 / h in capacity.

It is mainly used in small medium-sized cement plants as primary crushing feed for raw lime ore, also suitable for metallurgy, coal, chemical industry, electric power, building materials, machinery manufacturing other industrial sectors.

[production capacity]: 60-1100t / h

[feed size]: 500-1500mm

[motor power]: 11-45kw

Performance characteristics

1. The plate chain trough plate conveyor adopts two-point support, one end is directly placed on the crusher, the process layout is simple, the civil engineering cost is saved;

2. The tail device of the plate chain trough plate conveyor adopts a special design, which is suitable for rainy humid areas, will cause the chain tooth skipping phenomenon due to the accumulation of sticky wet materials at the tail, which will affect the production;

3. There are sleepers at the end of the plate chain conveyor to absorb vibration, a number of special shock absorbing rollers in the middle of the conveyor to improve the stress conditions of the impact of large materials on the rollers trough plates on both sides, so as to improve the service life of the running parts;

4. In particular, the lower cover of the head cover can be separated the left right, which may hinder the lifting of the crusher rotor body;

5. The traction chain the bearing chain are separated, the dynamic load is small, the service life is improved;

6. The head sprocket has 13-15 teeth, the odd even number of teeth are driven separately, so the service life can be doubled;

7. The sprocket of the head device is cut into 3 teeth, which can be replaced without removing the chain plate is easy to maintain;

8. The width parameters of plate chain conveyor are designed according to the standards of f.l.smidth (Denmark) AUMUND (Germany).

The maintenance of plate chain trough conveyor is an extremely important regular work. It should be closely coordinated with the operation maintenance of the conveyor. There should be full-time personnel on duty for inspection.